via-in-pad issue (standard technology)

Views : 1619

Author : meidear

Update time : 2020-03-10 16:51:49

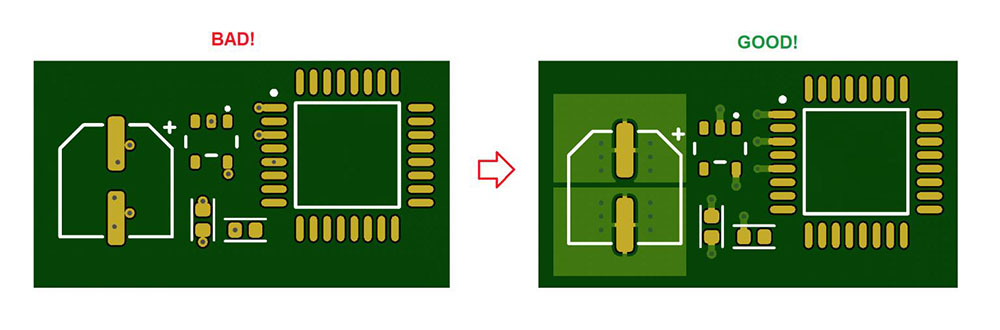

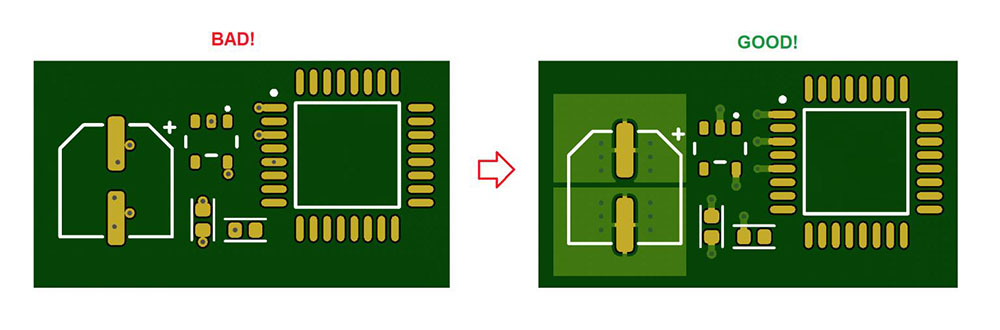

DFM/DFA/DFT Tips&Tricks - TIP #03 => via-in-pad issue (standard technology)

Whenever possible, always use enough clearance for the solder mask between the via and the copper pad to prevent solder flow into the via hole and can cause the solderability issues during the assembly and manufacturing process.

This note applies only to standard technology, especially typical 2-layer PCBs.

Please remember, that for multilayer HDI PCBs there is a similar via-in-pad technique (mostly used for small pitch BGAs), but that vias are additionally filled and plated.

There are some exceptions, such as RF circuits, high-current designs or BGA layouts, where that recommendation can be omitted.

Whenever possible, always use enough clearance for the solder mask between the via and the copper pad to prevent solder flow into the via hole and can cause the solderability issues during the assembly and manufacturing process.

This note applies only to standard technology, especially typical 2-layer PCBs.

Please remember, that for multilayer HDI PCBs there is a similar via-in-pad technique (mostly used for small pitch BGAs), but that vias are additionally filled and plated.

There are some exceptions, such as RF circuits, high-current designs or BGA layouts, where that recommendation can be omitted.

Related News

Comparison of LDI and CCD Exposure Systems

Apr .03.2025

In the PCB (Printed Circuit Board) manufacturing process, exposure is a critical step. Many PCB manufacturers like meidearpcb utilize CCD semi-automatic exposure machines for this process.

LED lighting PCB (Printed Circuit Board) Solutions

Jan .01.2025

LED lighting PCB (Printed Circuit Board) solutions

CEM-3 Thermal conductive material

IMS pcb Flexible pcb Copper-base pcbs

CEM-3 Thermal conductive material

IMS pcb Flexible pcb Copper-base pcbs

How many types of surface treatment processes for PCB?

Dec .20.2024

PCB surface treatment processes

HASL,OSP ENIG,Immersion Silver,Immersion Tin hard Gold

nickel P-alladium gold

HASL,OSP ENIG,Immersion Silver,Immersion Tin hard Gold

nickel P-alladium gold

The material difference between high-frequency PCB and high-speed PCB

Sep .03.2024

Professional production, high-frequency, high-speed, HDI, LED lighting board, (Flex, Rigid-Flex,) (Wangling, Taiyao, Nanya, Isola, Rogers, Pana-sonic,) Quotation email: mkt@me-pcb.com