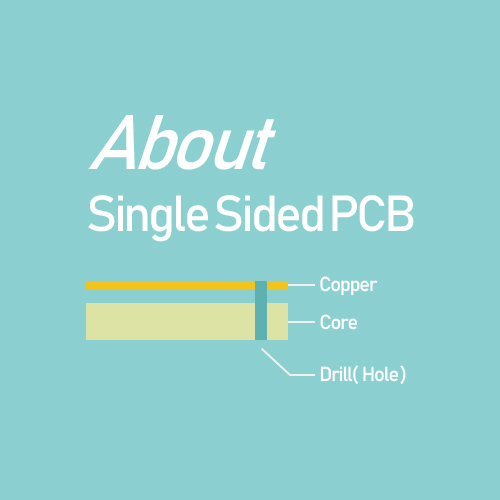

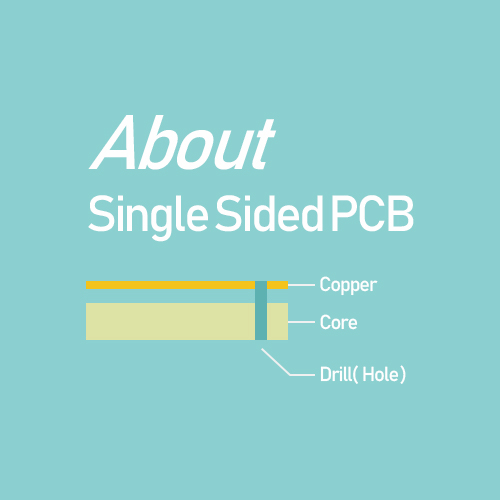

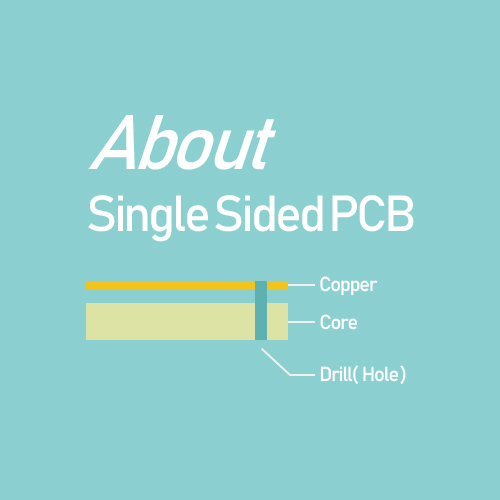

Single-double Sided PCB

What is FR4 single sided PCB

Copper thicknesses: 1Oz 2Oz 1.5Oz, 3Oz

copper-clad laminate (CCL)

Core: glass-reinforced epoxy laminate material

copper-clad laminate (CCL)

Core: glass-reinforced epoxy laminate material

Description

What is FR-4(FR4) PCB material?

FR-4 (or FR4) is a NEMA grade designation for glass-reinforced epoxy laminate material. FR-4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant (self-extinguishing).

"FR" stands for flame retardant, and does not denote that the material complies with the standard UL94V-0 unless testing is performed to UL 94, Vertical Flame testing in Section 8 at a compliant lab. The designation FR-4 was created by NEMA in 1968.

FR-4 epoxy resin systems typically employ bromine, a halogen, to facilitate flame-resistant properties in FR-4 glass epoxy laminates.

Most printed circuit boards are manufactured using glass-reinforced epoxy laminate as the substrate. While there are a wide variety of laminates available on the market, FR-4 is both versatile and well-accepted as a standard material for PCB manufacture. FR-4 functions well as an electrical insulator, and has a good strength-to-weight ratio, and is flame resistant.

The standard FR-4 material that is used in our products is a high temperature, high Td, low CTE 150Tg material.

In a typical PCB, the core provides the rigidity and the foundation on which the PCB traces can be ‘printed’ onto. In addition, the FR4 core and laminates form the electrical isolation separating copper layers.

What is single sided PCB?

FR-4 (or FR4) is a NEMA grade designation for glass-reinforced epoxy laminate material. FR-4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant (self-extinguishing).

"FR" stands for flame retardant, and does not denote that the material complies with the standard UL94V-0 unless testing is performed to UL 94, Vertical Flame testing in Section 8 at a compliant lab. The designation FR-4 was created by NEMA in 1968.

FR-4 epoxy resin systems typically employ bromine, a halogen, to facilitate flame-resistant properties in FR-4 glass epoxy laminates.

Most printed circuit boards are manufactured using glass-reinforced epoxy laminate as the substrate. While there are a wide variety of laminates available on the market, FR-4 is both versatile and well-accepted as a standard material for PCB manufacture. FR-4 functions well as an electrical insulator, and has a good strength-to-weight ratio, and is flame resistant.

The standard FR-4 material that is used in our products is a high temperature, high Td, low CTE 150Tg material.

In a typical PCB, the core provides the rigidity and the foundation on which the PCB traces can be ‘printed’ onto. In addition, the FR4 core and laminates form the electrical isolation separating copper layers.

What is single sided PCB?